STRESSES

In static and dynamic

bodies are considered as rigid the bodies do not undergo any change in shape

under the action of force in contrast strength of materials deals with the

behavior of the bodies under the action of external loads. Moreover the

deformation (bodies are no longer assumed to be rigid) under the load is the

major interest and an attempt is made to find out whether or not a given member

fail under the load. The basic concepts of strength of materials are discussed

in this chapter.

Loads:

Any external forces acting on a component are

called loads. The loads may be classified as given below.

a)

According to the manner in which they are applied.

1)

Point or concentrated loads

2)

Distributed loads

Point or concentrated load acts over a very small area

which is considered as a point it is expressed in N or KN.

Load distributed over an area or along a length is

called distributed load a load may be uniformly or non-uniformly distributed

along a length or an area it is expressed in N/m² or N/m.

b) According to the nature of

action:

I.

Static load

II.

Dynamic load

III.

Fluctuation or cyclic load.

Static load gradually increases from zero to a

certain value and them remains constant during entire time of its application.

Dynamic load refers to the impact or falling load which time duration is a

small fraction of second. Fluctuation or cyclic load refers to the load in

which its magnitude and direction varies continuously.

C) According to the effect

produced:

- Axial load

- Tensile load

- Compressive load

- Shear load

- Bending load

Axial loads are applied

along the longitudinal axis of the structural member if the action of load is

to increase the length of the member the member is said to be in tension and

the applied load is tensile load. A load which tends to shorten a member and

place the member in compression is known as a compressive load. Shear loads act

perpendicular to the axis of a structural member it tends to slides the surface

with respect to other or to cut the part. Bending load is transverse load

tending to bend the structural member.

Stress:

When load acts on a body the internal resistive

force (strength) resists deformation. This internal force is equal and opposite

to the external load. The total resistance per unit area of cross-section is

called induced stress or stress. Stress is usually denoted by σ and if a is the

cross-sectional area normal to the load then

Stress = load/area of

cross-section

σ = P/A N/mm²

In SI units the stress is expressed in N/m² or

N/mm² it may be noted that

Type of

stresses:

Depending

on the direction of load the following types of simple stresses are induced in

a component.

·

Tensile stress

·

Compressive stress

·

Shear stress

Tensile

stress:

The load acting along the axis and perpendicular to

the area of cross-section is called normal or axial load the axial load tending

to stretch the bar is called tensile load and corresponding stress induced is

called tensile stress.

Tensile stress σ₁ =

tensile load/area of cross-section

σ₁ =P/A

Compressive

stress:

The

axial load tending to compress the block is called compressive load and the

stress induced is called compressive stress.

Compressive

stress σc = compressive load/ area of cross-section

Shear

stress:

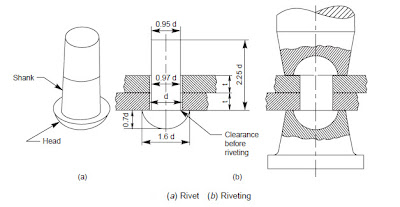

The tangential load tending to cut or slide the

part is called is shear load and the corresponding stress induced is called

shear stress in this case load tangential to the area over which it acts.

Shear stress τ= shear load/area of cross-section

τ = P/A

Comments

Post a Comment